Modern manufacturing depends on strong machinery. Rotary devices keep operations in constant motion. Compressors turbines and pumps perform vital tasks. These machines push fluids and gases with steady force. They drive the flow of materials in many plants. Energy moves efficiently from one stage to another. Each process step runs without pause. Industries rely on such systems for stability. The smooth flow of production means fewer delays. Equipment keeps the rhythm of industrial life. Without this power many facilities would halt.

Rotary Equipment in Diverse Sectors

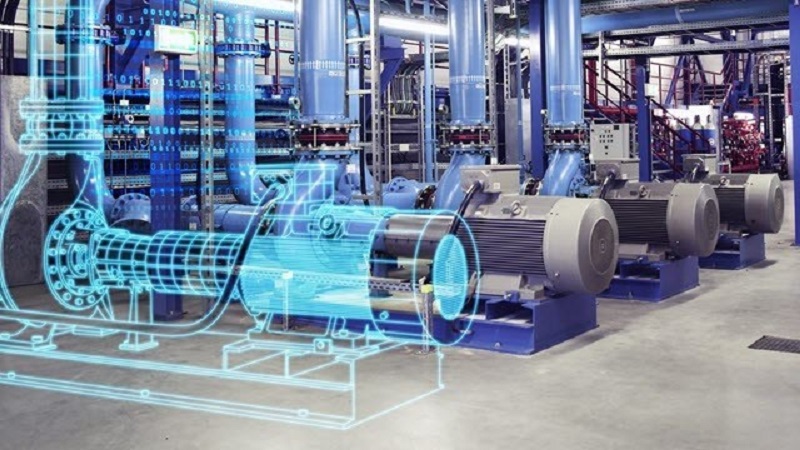

The reach of these machines covers many fields. Rotary equipment serves petrochemical sites and food plants. It also supports water treatment plants daily. These machines assist in packaging and mixing. They compress air or liquids for systems. Power flows through them in steady cycles. The design allows long operation without rest. Engineers choose durable materials for each build. Rotary equipment also cuts energy waste. This improves the output of the plant. Each unit works toward higher efficiency goals.

Continuous Motion for Critical Processes

So, the success of industry depends on motion. Pumps maintain flow through dense pipelines. Compressors keep pressure in safe ranges. Turbines spin to create needed power. Factories and refineries count on this daily. The power moves products from start to finish. Heat exchange systems also need steady flow. Smooth operation limits breakdown risks in plants. Stability means more consistent quality for goods. Each step-in production links to another. The chain stays strong when parts work in sync.

Efficiency and Energy Management

As energy costs rise the need for efficiency grows. Rotary machines reduce waste through steady operation. Maintenance extends their life span and output. Operators check systems for wear and fault signs. The design of each unit supports easy service. Pumps and turbines use refined structures. The power they generate is dependable and steady. This means less downtime for any site. Better output leads to higher returns. Industries gain as systems run longer hours. The result is a stronger manufacturing base.

The Role of General Kinematics

General Kinematics offers critical financing solutions for these systems. Many plants invest in new rotary devices through such support. This allows upgrades without cash strain. Financing helps smaller firms join the market. Companies can replace outdated pumps and compressors. The right equipment improves overall production. General Kinematics works with clients to meet needs. Flexible plans make larger projects possible. Modern equipment can be installed with less delay. The result is better output and higher safety.

Conclusion

If manufacturing loses its motion the economy slows. Rotary machines keep goods moving day and night. They work in silent service to every industry. The flow they maintain builds national output. Each pump turbine and compressor have a role. Modern financing from firms makes upgrades easier. General Kinematics stands as a partner in growth. Plants using advanced machines stay ahead of rivals. Efficiency grows as technology moves forward. The heart of industry will keep beating.