Heat exchangers play a crucial function in efficient warmth switch throughout varied industries. These units are designed to transfer heat from one fluid to another, maximizing thermal efficiency and decreasing vitality consumption. Whether it is in heating methods, refrigeration models, or power plants, heat exchangers are extensively utilized for their capacity to reinforce heat transfer processes.

Understanding Heat Exchangers

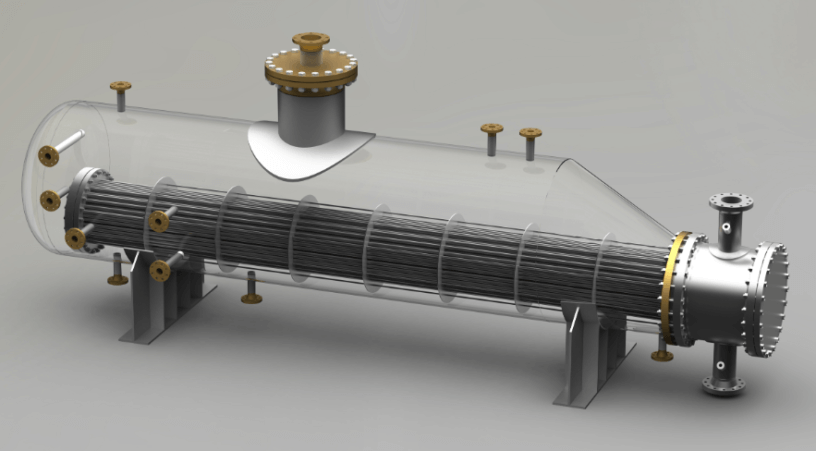

A heat exchanger is a mechanical device that facilitates the transfer of heat between two fluids. It consists of tubes, plates, or coils that enable the trade of thermal vitality without direct contact between the fluids. The two major forms of heat exchangers are the shell-and-tube and plate warmth exchangers.

In a shell-and-tube heat exchanger, one fluid flows inside the tubes whereas the opposite circulates round them. This design permits for efficient warmth switch because of the giant surface area offered by the tubes. On the other hand, plate heat exchangers use corrugated plates to create a quantity of paths for the fluids, maximizing warmth transfer via turbulent flow.

The Importance of Efficient Heat Transfer

Efficient warmth switch is significant in numerous applications as it permits effective temperature control, enhances power effectivity, and reduces working costs. Heat exchangers facilitate this course of by minimizing warmth loss and optimizing heat exchange between fluids.

In heating systems, heat exchangers assist heat up cold air by passing it over scorching water or steam-filled tubes. The heat is transferred from the heated fluid to the encompassing air, ensuring snug indoor temperatures. In refrigeration items, warmth exchangers work in reverse, dissipating warmth from the cooled house to maintain up low temperatures.

Moreover, heat exchangers are widely used in power plants to improve the overall efficiency of energy conversion processes. By capturing waste heat microchannel heat exchanger from exhaust gases, heat exchangers can preheat incoming water or generate steam, reducing the amount of fuel required for power generation.

Enhancing Heat Transfer Efficiency

To maximize heat transfer efficiency, various techniques and design considerations are employed in heat exchanger techniques. These embrace growing floor space, bettering fluid circulate patterns, and enhancing thermal conductivity.

Increasing the floor space of heat exchanger parts, corresponding to utilizing finned tubes or adding extra plates in plate heat exchangers, enhances warmth switch by providing a larger contact space between the fluids. This allows for larger heat trade and improved general efficiency.

Controlling fluid circulate patterns is one other key consider optimizing warmth transfer. Turbulent circulate, achieved via appropriate flow velocities or channel geometries, promotes efficient heat change by disrupting boundary layers and enhancing fluid mixing. This ensures that the maximum quantity of warmth is transferred between the fluids.

In addition, choosing materials with excessive thermal conductivity for warmth exchanger elements improves their capacity to conduct heat. Metals like copper and aluminum are commonly used due to their excellent thermal properties. These supplies decrease resistance to warmth switch and enhance overall system efficiency.

In Conclusion

Heat exchangers are indispensable devices for efficient warmth switch in varied industrial applications. By facilitating the trade of thermal power between two fluids, these units play a crucial role in sustaining optimal temperatures, reducing vitality consumption, and enhancing total system efficiency. Through steady improvements in design and expertise, warmth exchangers contribute to a extra sustainable and energy-efficient future.