Before getting into the details, it is first important to understand the meaning of a servo control system. The concept of servomechanism originates in control engineering. A servomechanism is referred to as a servo. A servo is an automatic device. This automatic device regulates the action of a mechanism. The servomechanism corrects the action of mechanisms when it senses an error in the form of negative feedback. A servo system (ระบบ เซอร์ โว, which is the term in Thai) has several applications. To learn more about servos, continue reading.

The Basic Parts Of A Servo

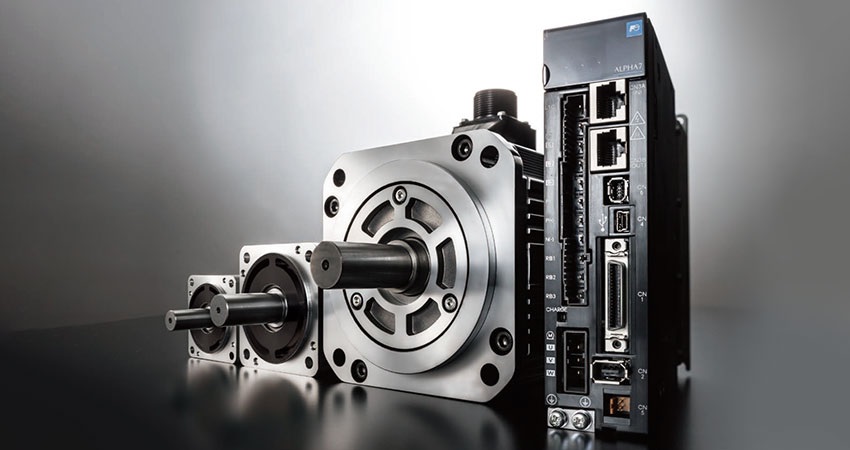

Every servo motor has three fundamental components. These three main elements are a controller circuit, a DC motor, and a potentiometer. A servo works because these three main elements work in collaboration with each other. The DC motor is connected to the input/output shaft and the gearbox. This increases the motor’s torque and speed. The output shaft is controlled by the DC motor. The second component, that is, the circuit controller performs the role of interpreting any signal sent by the controller. The potentiometer is the feedback system for the servo motor. It serves as the feedback system for the circuit controller. This ensures that the position of the output shaft is monitored.

Servo Sizes

Closed-loop servos, also known as standard hobby servo systems, come in three different sizes. The size of a service refers to two parameters of a servo motor- the power and output torque, and the actual physical size of the servo motor. The three sizes are:

- Micro: This servo motor size occupies the least amount of space. The torque output of this servo motor type is also low. The power requirement of this servo type is also low.

- Giant: This servo motor requires the most space. The power requirements of this servo motor are also very high. As a result, the torque output of this servo motor is also very high.

- Standard: This servo motor is the best middle-ground option. This is because its power requirement is lower than the giant size. It also requires less space than a giant size servo motor. The output torque is adequate and therefore, this motor type finds the most number of applications.

Apart from size, servos can be classified under another typology, based on their performance. There are two basic types of servo motors- the closed-loop servo, also known as the standard hobby servo system, and the open-loop servo also called the continuous rotation servo.